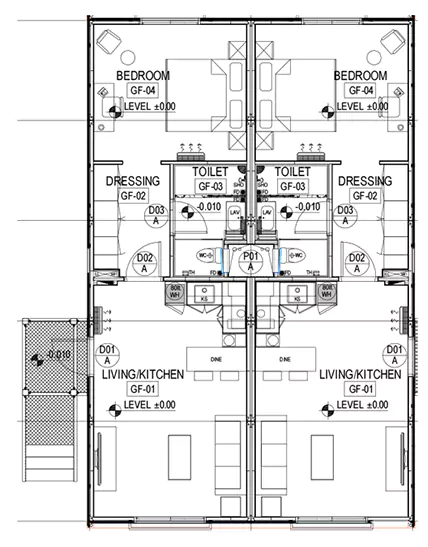

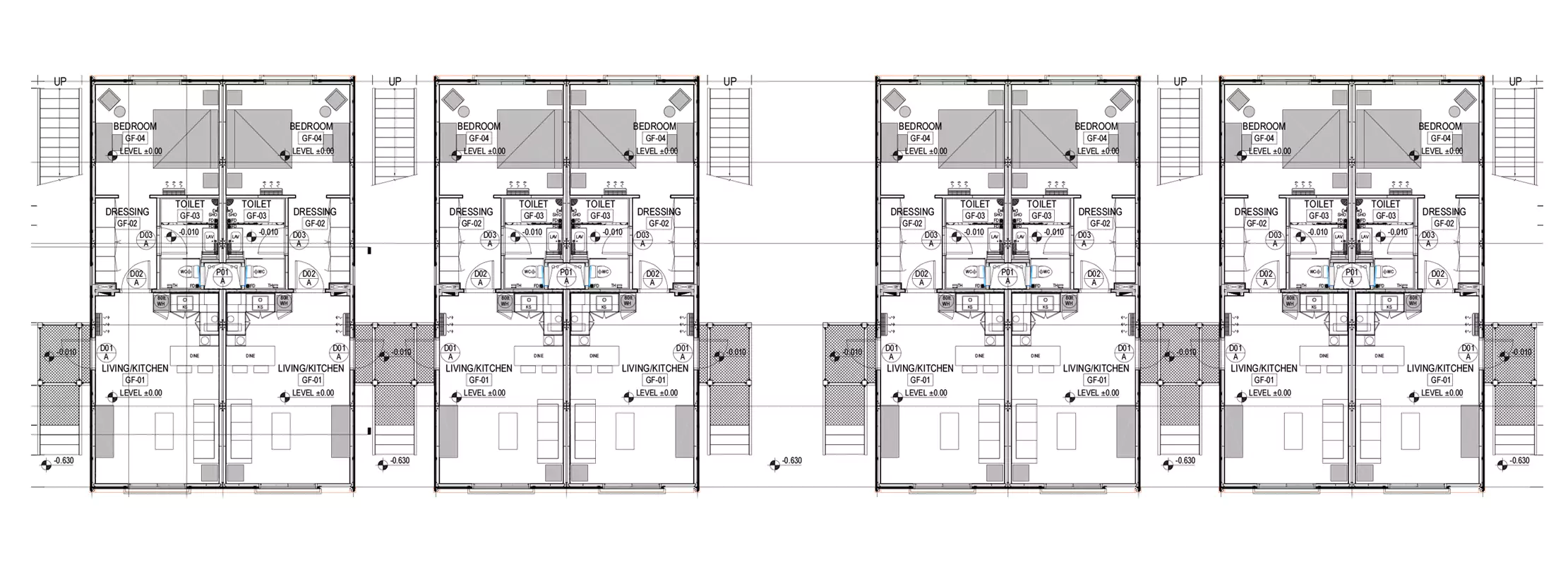

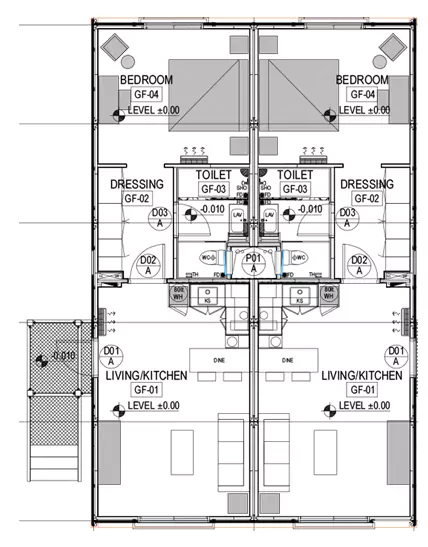

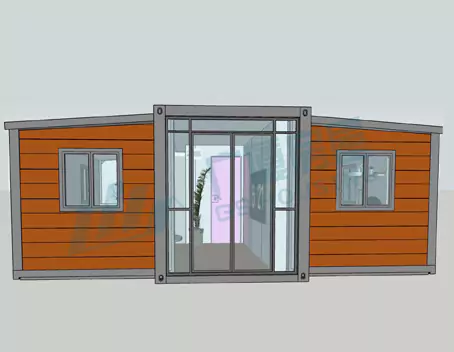

- Length: 8060mm

- Width: 12500mm

- Height: 6500mm

- Area: 44.8㎡

- Type: two layers

- Each unit consists of: one bedroom, one living room, one kitchen, and one bathroom

With the ongoing development of the global housing market, container houses, with their multiple advantages, have gradually become a popular alternative housing solution in some developed countries.

1. Cost-Effective

● Low Cost: Compared to traditional housing, container housing offers significantly lower construction and maintenance costs.

● Recycling and Reuse: Utilizing second-hand containers further reduces construction costs while promoting environmental sustainability.

2. Quick Construction

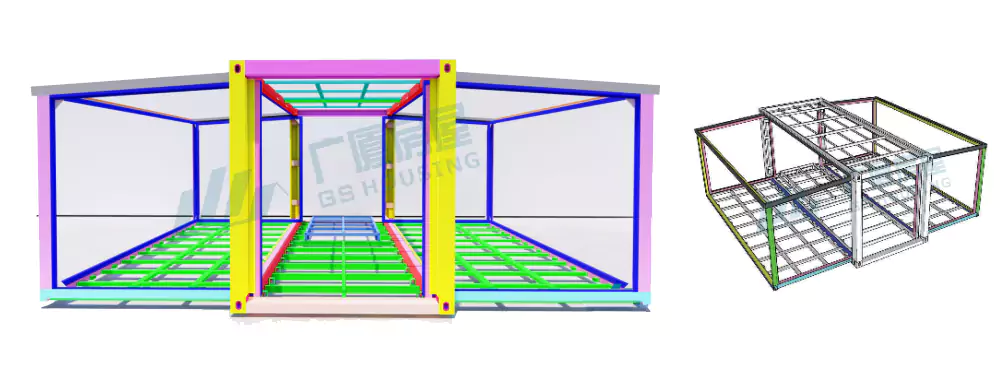

● Prefabricated Structures: Containers are prefabricated, requiring only basic modifications and installation for use. They are particularly suitable for temporary or emergency housing needs.

● Efficient Production and Installation: The components of container housing are produced in factory assembly lines, ensuring a short construction period. GS Housing provides easy-to-install container solutions along with detailed installation instructions, drawings, and videos. For specific projects, engineers can be dispatched to the site for installation guidance.

3. High Flexibility

● Mobility: Container structures can be easily relocated, making them ideal for people who need frequent location changes.

● Modular Design: Containers can be freely combined or stacked based on specific needs, creating diverse and adaptable spaces.

4. Environmentally Sustainable

● Reduced Construction Waste: Compared to traditional construction methods, container housing reduces construction waste by approximately 70% and saves around 50% in energy consumption.

● Resource Reuse: Containers can be reused multiple times without damage, providing a fast and cost-effective solution.

5. Strong Adaptability

● Adaptable to Various Environments: Container housing is well-suited for urban, rural, or remote areas.

● Specialized Applications: Frequently used as temporary shelters in response to natural disasters or emergencies, such as earthquake relief housing.

6. Long Service Life

● Durable and Reliable Structure: Container housing offers earthquake resistance up to magnitude 8 and wind resistance up to level 12. With a service life exceeding 20 years, it also features earthquake resistance, compression resistance, insulation, soundproofing, fire resistance, water resistance, and wind resistance.

Specifications

| NO. | NAME | SPECIFICATION |

| 1 | Main beam for the top frame | Material: Q355B,t=3.0mm ,Galvanized cold roll steel,Galvanizing amount 275g/㎡ |

| 2 | Main beam for the bottom frame | Material: Q355B,t=3.5mm ,Galvanized cold roll steel,Galvanizing amount 275g/㎡ |

| 3 | Column | Material: Q355B,t=4.0mm ,Galvanized cold roll steel,Galvanizing amount 275g/㎡ |

| 4 | Secondary beam for the top frame | Material: Q355B,t=1.5mm ,Galvanized cold roll steel,Galvanizing amount 275g/㎡ |

| 5 | Secondary beam for the bottom frame | Material: Q355B,t=2.0mm ,Galvanized cold roll steel,Galvanizing amount 275g/㎡ |

| 6 | Insulation material for the top and bottom frame | 100mm thick rock wool felt with aluminum foil on one side, bulk density ≥60kg/m³, combustion performance is Class A non-combustible; |

| 7 | External wall panels | 50mm thick color steel sandwich panel, with a 0.5mm corrugated galvanized color steel outer layer, a 0.5mm aluminum-zinc color steel inner layer, and rock wool density of 100kg/m³. |

| 8 | Inner wall panel | 70mm thick color steel sandwich panel, with a 0.5mm corrugated galvanized color steel outer layer, a 0.5mm aluminum-zinc color steel inner layer, and rock wool density of 80kg/m³. |

| 9 | Gypsum board | ordinary gypsum board 、 moisture-proof gypsum board、 fireproof gypsum board |

| 10 | Sloping roof | 0.5mm thick V-840 white-gray color steel tile, 2C KZ system, with a zinc coating of 275g/㎡; cornices and columns are made of 0.8mm color steel plate. |

| 11 | Door | Black, fireproof for 60 minutes, master key |

| 12 | Window | The glass is made of transparent low-emissivity 8lov-e+16A+6+0.76pvd+ coated low-transmittance tempered laminated insulating glass |

Design Drawings