- Prefabricated container houses are widely used in the oil and gas industry for their modular design, rapid deployment, and durability in extreme environments. GS Housing’s oilfield container units are factory-assembled and delivered ready-to-use, allowing workers to move in on the same day of installation.

- Tailored to your project – choose from flexible layouts, and sizes, all with the speed and efficiency of modular container house steel construction.

- Certifications: ISO / CE / ASTM / SGS / SASO / GOST-R / UL / BUREAU VERITAS

In the oil and gas industry, camp construction often faces challenges such as tight project schedules, harsh environments, and remote locations. Traditional building methods require long construction cycles and high costs, making it difficult to meet the needs of rapid deployment and flexible adjustments in oilfield projects. Prefabricated container houses, with their modular design, standardized production, and fast installation, have become an ideal solution for accommodation and office facilities in oilfield operations.

GS Housing’s oilfield container houses are fully prefabricated and assembled in the factory. Each unit is delivered with essential facilities already installed, including electricity, plumbing, and interior fittings. Once transported to the site, the modules can be lifted into position and made ready for use the same day. This “plug-and-play” approach significantly shortens the construction period, saving valuable time for oilfield projects and ensuring faster project execution.

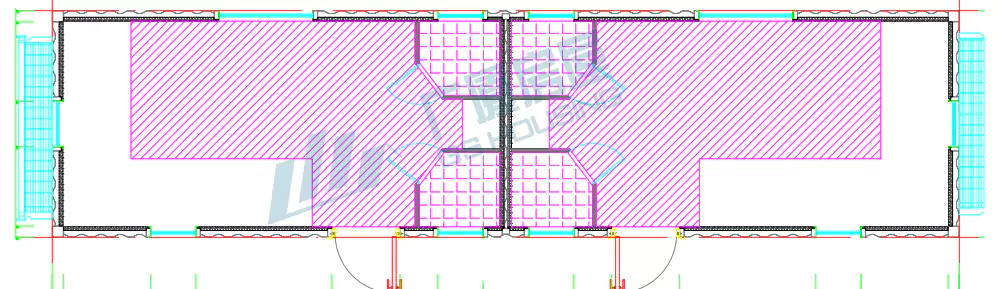

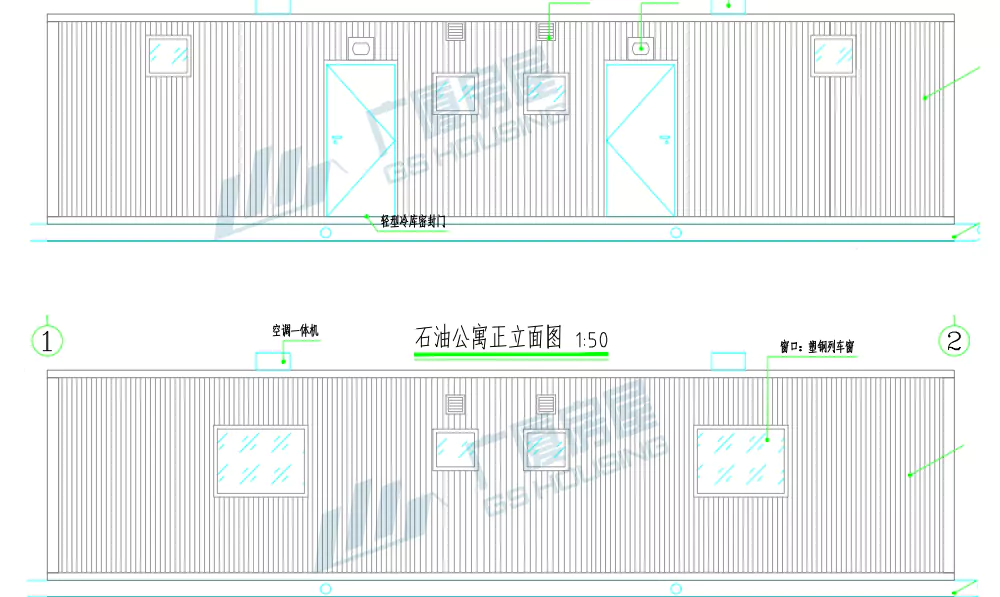

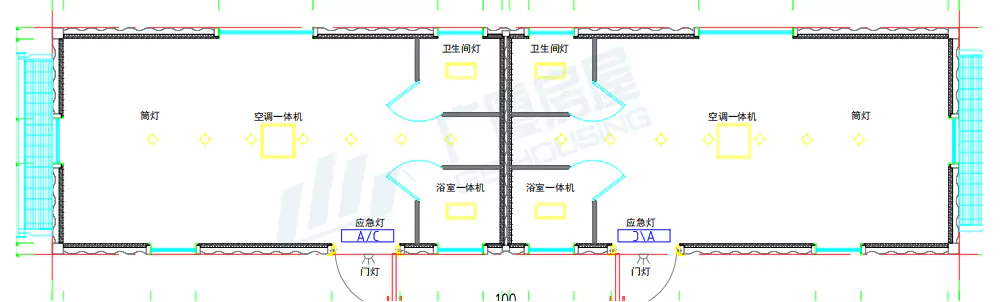

Designed for both comfort and durability, each living unit is divided into two separate rooms. The layout includes a refrigerator, water heater, air conditioner, television, and private bathroom, ensuring a comfortable living environment even in deserts, extremely cold regions, or areas prone to sandstorms. Beds, showers, and sanitary areas are arranged in a compact yet efficient manner to maximize the use of limited space. Each room can accommodate multiple people, striking a balance between practicality and comfort.

The structural design of the container houses also takes extreme conditions into account. The roof is built with 2mm corrugated steel sheets reinforced with 10mm steel eaves plates, providing strong load-bearing capacity, insulation, waterproofing, and effective drainage. This ensures that the housing units remain stable and reliable even in the most challenging weather conditions.

In addition to accommodation, the modular structure allows for flexible combinations to create diverse functional spaces such as office areas, dining halls, meeting rooms, or even emergency medical stations. This adaptability enables oilfield companies to establish fully functional camps that can be quickly adjusted based on project requirements and workforce size.

With durable construction, comprehensive facilities, and rapid deployment capability, GS Housing’s prefabricated container houses provide an efficient and reliable solution for oilfield camps. They not only solve the pressing needs of housing and office space in oilfield operations but also open up new possibilities for global project development.

Design Drawings

|

|

|

| Internal Configuration |

|

|

|

|

| Modular Container Bunk Beds | Modular Container Living Space | Container Bathroom |

| Functional application scenarios |

|

|

|

|

| Modular Container Bunk Beds | Modular Container Living Space | Container Bathroom |

|

|

|

| Bathroom | Washroom | Laundry room |

For more information, you can contact us.

| Why Choose GS Housing |

| Authorative Certification |

| After-sales Service | |

| 1 | Do you provide on-site installation service? We provide very detailed installation instruction drawings and videos for every project.For large projects, we will have both installation workers and supervisors on site.The fee for the on-site service should be negotiated with clients. |

| 2 | What’s your delivery time? Normally, delivery time is 7-10 days after deposit received. For large order, the delivery time should be negotiated. |

| 3 | How to control the quality of your product? 1. quality of the design: think about possible problems in advance and provide a high-quality design solution. 2. quality of the raw material: choose the qualified raw material 3. quality of the production: precise manufacturing technique, experienced workers, strict qualit inspection. |

| 4 | How to deal with quality problems? Warranty is 1 years. Within the warranty period, GS Housing will responsible for all quality problems caused by our production. |

| 5 | If there is a clear service life of your products? If have,how long? Under conventional climate and environment, the service life of container house steel frame is 20 years |

| 6 | What designs do you have in different climates (How can the products adopt to different climates)? Strong wind region: improve the wind-resisting ability of the internal structure. Cold region: increase the thickness of the wall,or use good insulation material, improve anti-pressure ability of the structure. High corrosion region: use corrosion resistant material, or paint anti-corrosive coating. |

Leave Your Message

For more information, please fill out the form, and we will respond to you via email within 24 hours.