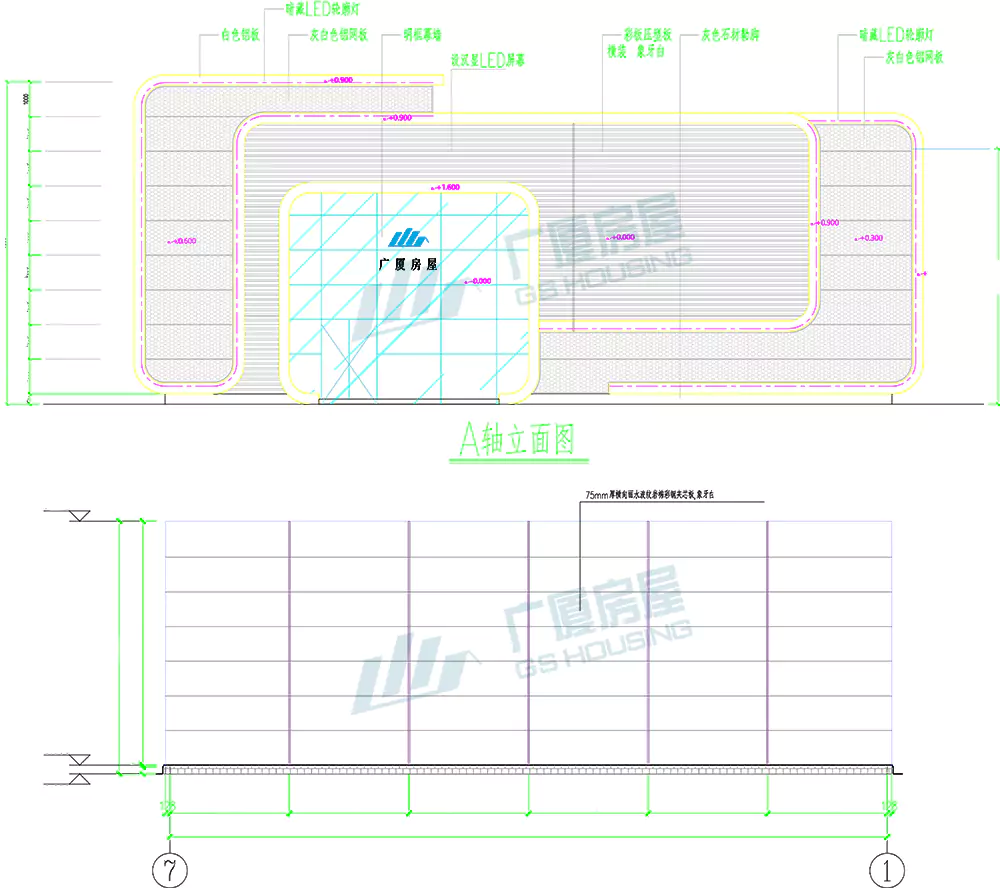

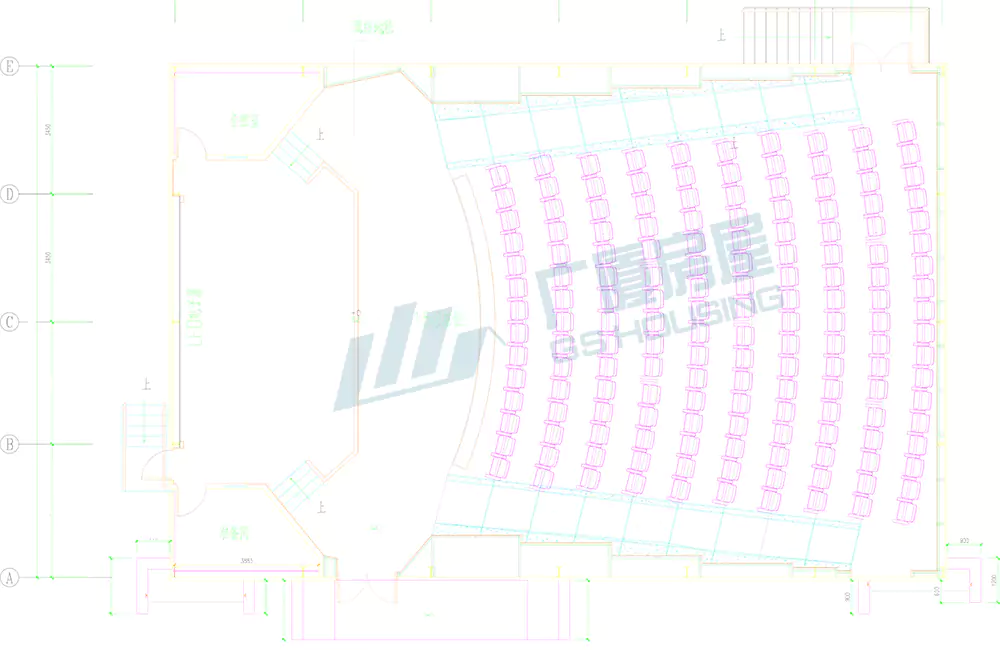

- Length: 20700mm

- Width: 13560mm

- Height: 7500mm

- Area:293.03㎡

- Use:Large conferences, performance theaters、Workshop or Factory building

GS HOUSING Characteristics of prefabricated light steel structure houses

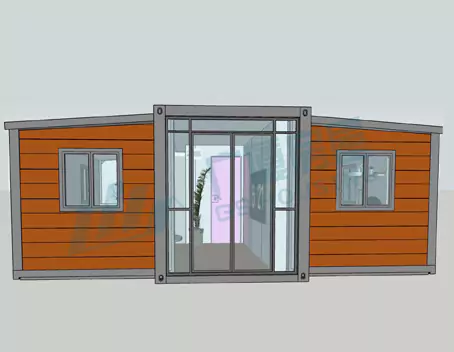

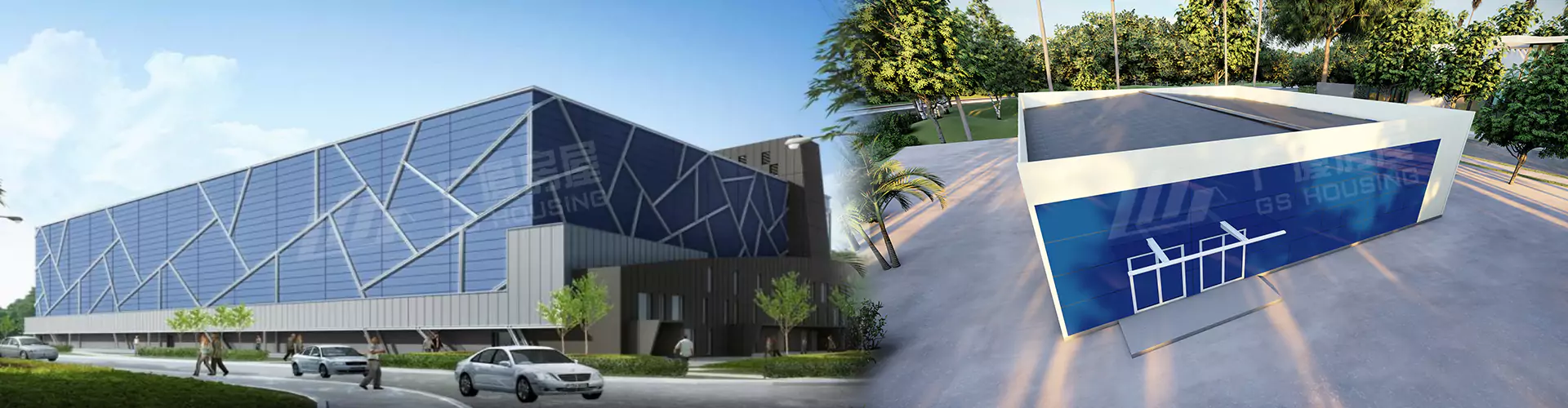

GS HOUSING prefabricated light steel structure houses are a modern form of construction that uses cold-formed thin-walled steel as the primary load-bearing component. The main framework is made of high-strength galvanized steel, combined with high-performance materials such as insulation, heat resistance, and fireproof materials, creating a complete and efficient building system. This structure is not only lightweight and strong but also boasts excellent seismic and wind resistance, easily handling complex environments to ensure the safety and stability of the building.

GS HOUSING Advantages of Prefabricated Light Steel Structure Houses

The cladding materials and insulation are made of Class A non-combustible glass wool or rock wool, further enhancing the building’s fire resistance and energy efficiency. During construction, no painting or welding is required, and the assembly rate can reach 100%, making it both environmentally friendly and efficient. With fast construction speed, low maintenance costs, and long service life, it offers an exceptional cost-performance ratio compared to traditional building methods, making it an ideal choice for modern construction.

GS HOUSING Application Range of Prefabricated Light Steel Structure Houses

The applications of GS HOUSING light steel structure houses are diverse, covering residential homes, villas, guesthouses, office buildings, schools, hospitals, and more. They can also be used to build conference rooms, sports venues, large factories, and other varied scenarios, meeting the diverse needs of different clients.

GS HOUSING Transportation of Prefabricated Light Steel Structure Houses

In terms of transportation, a 40-foot shipping container can transport at least 300 square meters of fast-assembly homes. For land transport, only one 4.5-meter and one 12.6-meter truck are required to complete the delivery, with over 90% loading efficiency, significantly reducing logistics costs and improving the economic and logistical convenience of the project.

Moreover, the light steel structure has low foundation requirements, adapting to various complex terrains and environments, demonstrating strong flexibility. For example, a 300㎡ building can be installed in just about five days, achieving high installation efficiency and significantly shortening the project timeline, helping clients quickly achieve their construction goals.

GS HOUSING Service Solutions for Prefabricated Light Steel Structure Houses

With its reliability and innovation, GS HOUSING light steel structure houses are committed to providing clients with efficient, environmentally friendly, and safe building solutions. Our vision is to become the most qualified modular housing system service provider, with the corporate motto, “Quality is the dignity of the enterprise,” as our guiding principle, supporting each of our clients in realizing their building dreams.

Specifications

| Specification Table | ||

| Product Specifications | Specifications | L:n*kz W:3kz/4kz |

| Common Span | 3kz/4kz | |

| Standard Column Spacing | kz=3.45m | |

| Indoor Clear Height | 4m/4.4m/5m | |

| Design Parameters | Structural Service Life | 20 year |

| Standard Value of Live Load for Roof | 0.5kn/㎡ | |

| Standard Value of Dead Load for Roof | 0.5kn/㎡ | |

| Standard Value of Wind Load | 0.6kn/㎡ | |

| Seismic Design Intensity | 8度 | |

| Structure | Structural Type | 0.5mm thick V-840 white-gray color steel tile, 2C KZ system, with a zinc coating of 275g/㎡; cornices and columns are made of 0.8mm color steel plate. |

| Main Materials | Q345B | |

| Wall Battens | C120*50*15*1.8 Material:Q235B | |

| Roof Battens | C140*50*15*2.0 Material:Q235B | |

| Roof | Roof Panel | 0.5mm Color Steel Rock Wool Sandwich Panel (Polyurethane Edge Sealing) V-1000 Panel Type |

| Insulation Cotton | 50mm thick basalt wool, with a density ≥ 1000 kg/m³, and fire resistance rated as Class A. | |

| Drainage System | Organized drainage, 1mm thick 304 stainless steel roof gutter, U-PVC 110Φ110 drainage pipe (with parapet wall) | |

| Wall Surface | Wall Panel | 0.5mm Color Steel Glass Wool Sandwich Panel (Polyurethane Edge Sealing) V-1000 Transverse Lishui Corrugated Panel |

|

Insulation Cotton

|

50mm thick basalt wool, with a density ≥ 1000 kg/m³, and fire resistance rated as Class A. | |

| Doors and Windows | Door | 900*2100 / 1600*2100 /1800*2400 Steel Door |

| Windows | 5+12A+5Double Glazed Glass 1kz=3.45m 3kz=10.35m 4kz=13.8m; n=Number of Openings | |

|

Note: These are standard design parameters, and the specific design should be based on actual conditions and requirements. 1kz=3.45m 3kz=10.35m 4kz=13.8m; n=Number of Openings |

||

Design Drawings